Shopify Inventory Automation at Scale Using a Software+ System

When Inventory Management in Shopify Stops Being a Setting — and Becomes an Operational System

Shopify is built to support growth. But as stores scale, introduce complex product structures, and increase order velocity, inventory management becomes one of the first systems to fail.

At this stage, inventory is no longer a configuration task. It becomes a system-level operational challenge.

This case study documents how Webrex Studio implemented a Software+ inventory automation system for a high-growth Shopify Plus store — eliminating overselling risk, synchronising shared inventory across variants, and restoring operational confidence through a system designed for scale.

This was not an app install. This was not a workflow tweak.

This was a Shopify inventory system redesign.

Client & Operational Overview

- Platform: Shopify / Shopify Plus

- Business Model: Scaled DTC ecommerce

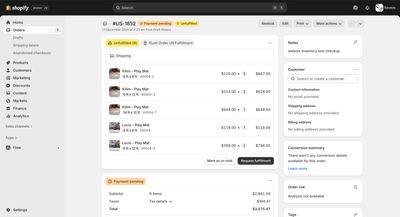

- Product Type: Size-based play mats with shared material inventory

- Catalog Structure: Multiple variants drawing from a single base inventory pool

- Fulfilment: Centralised warehouse (single source of truth)

- Operational Stage: Post-growth (manual inventory management no longer viable)

This distinction is critical — because the problem described below does not exist in early-stage Shopify stores.

The Operational Challenge: Why Shopify Inventory Breaks at Scale

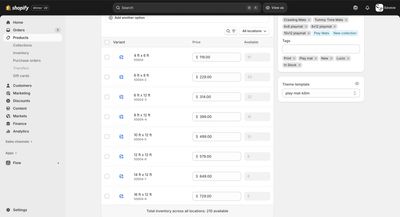

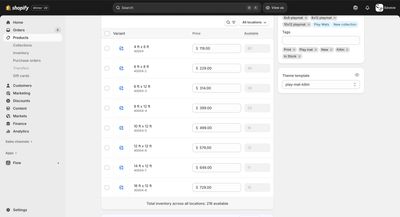

As the brand expanded its catalog, each physical product was sold in multiple size-based variants (e.g. 4×6 ft, 6×8 ft, 8×12 ft, etc.).

Operational Reality

- All variants were produced from the same base material

- Each variant consumed different quantities of that base inventory

- Availability needed to reflect shared stock, not individual SKUs

Native Shopify Behaviour

Shopify treats every variant as an independent inventory unit.

This assumption works for simple catalogs — but breaks when:

- Variants represent packs, sizes, or bundles

- Inventory consumption is shared

- Order volume increases velocity and risk

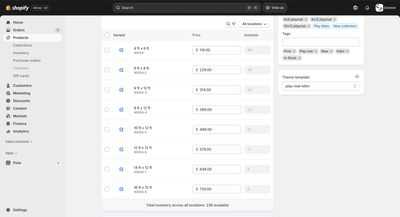

Inventory State Before System Implementation

Before automation, the Shopify admin displayed inventory per variant, even though all variants pulled from the same physical stock.

Problems observed:

- Storefront showed incorrect availability

- Larger sizes could be oversold even when base inventory was insufficient

- Operations teams manually recalculated inventory after orders

- High risk of human error

- Declining internal trust in inventory accuracy

Inventory had stopped being "admin work" and had become a system problem.

Why Manual Processes and Apps Failed

Before engaging Webrex Studio, the business attempted:

- Manual inventory adjustments

- Variant-level workarounds

- App-based inventory tools

These approaches failed because they:

- Adjusted numbers instead of recalculating truth

- Reacted after orders instead of enforcing logic

- Broke under SKU growth and order volume

What the business needed was not more automation, but a different inventory model.

The Software+ Inventory Automation Strategy

Webrex Studio designed a Software+ inventory system that operates alongside Shopify's native tools — extending them with logic rather than replacing them.

Core System Principle

Inventory must be recalculated from truth — not adjusted incrementally.

This principle guided the entire system design.

System Architecture Overview

The solution was implemented as a three-layer system, aligned with how top-performing Shopify Plus operations manage inventory at scale.

1. Trigger Layer — Shopify Flow

The workflow begins the moment an order is created.

- Trigger: Order Created

- Ensures inventory recalculation happens immediately

- Prevents lag-based overselling

2. Logic Layer — Software+ Core (Run Code)

This is where traditional Shopify automation stops — and system logic begins.

The logic layer:

- Reads order line items, variants, quantities, and fulfilment location

- Parses SKU structure to determine base unit consumption

- Converts the order into total base inventory used

- Recalculates remaining shared inventory

- Computes accurate availability for every dependent variant

Inventory is treated as math, not settings.

3. Execution Layer — Shopify Admin GraphQL

Once calculations are complete, the system applies updates in a single, controlled operation.

- Uses Shopify Admin GraphQL

- Performs bulk inventory adjustments

- Updates the correct fulfilment location

- Keeps all variants perfectly synchronised

Order-Level Validation

The system was validated against real, multi-line orders containing multiple sizes across different product families.

Each order:

- Correctly deducted base inventory

- Updated all related variants

- Prevented overselling in real time

Inventory State After Implementation

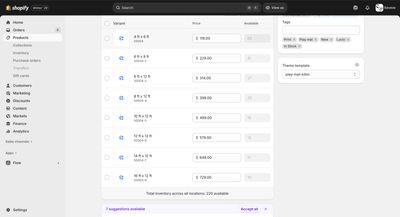

After deployment, inventory behaviour aligned fully with physical reality.

Results observed:

- All variants always showed accurate availability

- Zero overselling incidents

- No manual inventory corrections required

- Operations team regained trust in inventory data

- System scaled automatically with order volume

Inventory moved from:

"Something we constantly fix" to "Something that just works."

Why This Is a Software+ System — Not Just Automation

This solution did not add logic inside Shopify.

It augmented Shopify with software thinking.

Software+ Means:

- Designing systems around operational reality

- Treating Shopify as a platform, not a constraint

- Building logic that scales with complexity

- Prioritising long-term stability over quick fixes

This is how mature Shopify Plus commerce stacks are built.

Who This System Is Built For

This approach is ideal for:

- Shopify Plus merchants

- High-SKU catalogs

- Size-based, pack-based, or bundle-based inventory models

- B2B + DTC hybrid operations

- Brands where inventory accuracy directly impacts revenue

It is intentionally not designed for early-stage stores.

Complex systems should only exist where complexity already does.

Webrex Studio's Role

Webrex Studio operates as a Software+ Shopify partner.

That means:

- We don't just configure features

- We design operational systems

- We solve backend commerce bottlenecks

- We think beyond storefronts into inventory, fulfilment, and scale

Growth exposes problems. Software+ thinking solves them.

Closing Perspective

Shopify enables growth. Software+ enables scale.

This case study reflects how Webrex Studio approaches complex Shopify inventory challenges — not with shortcuts, but with systems designed for long-term operational stability.